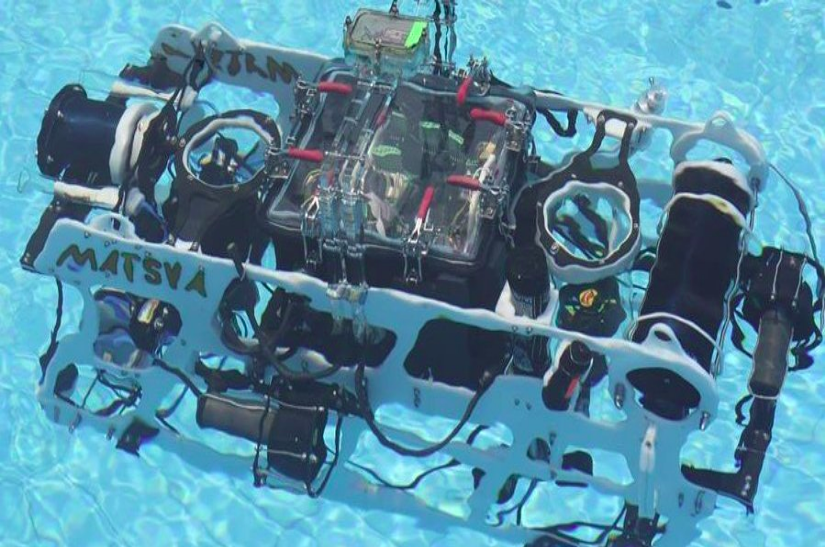

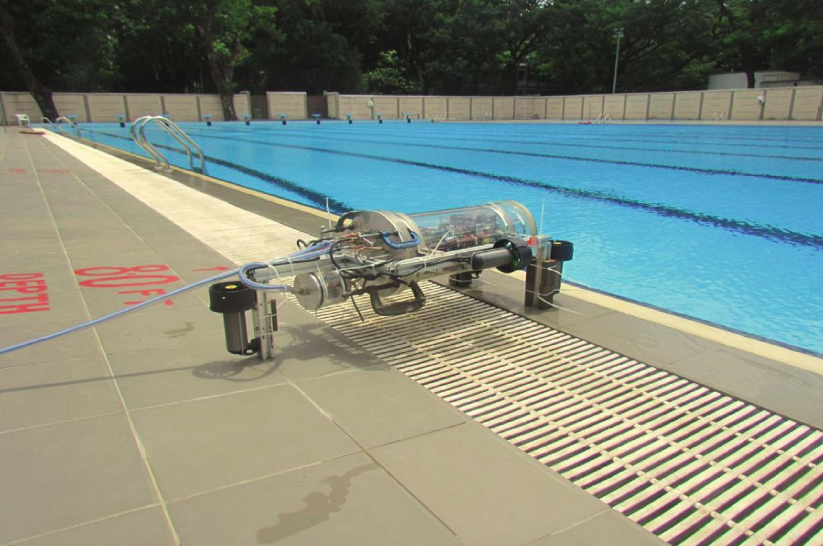

Team AUV-IITB

AUV-IITB comprises 55+ highly enthusiastic and hard-working technocrats on underwater robotics ranging from freshmen to driven senior undergraduates and experienced post-graduates spanning various branches of engineering at the Indian Institute of Technology Bombay.

About us